-40%

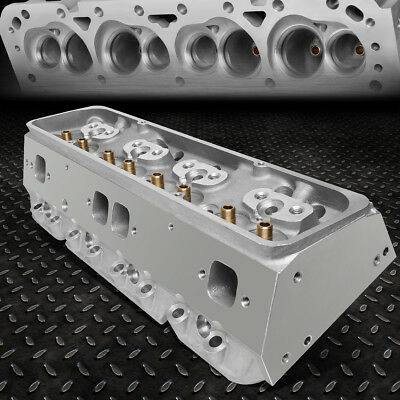

FORD 289 302 347 NKB-190cc ALUMINUM HEADS 62cc NKB-FORD-274

$ 469.39

- Description

- Size Guide

Description

FORD NKB 190cc/62cc ULTRA HIGH FLOW CYLINDER HEADS, 289 302 347 ENGINES.Setup for

hydraulic roller

cams.

190cc

RUNNERS,

62cc

COMBUSTION CHAMBERS

.

Important note.

Our eBay user id is:

skipwhite

, and our eBay store name is whiteperformance1. You may have noticed other sellers using a similar name offering similar products. These other sellers have capitalized on our name as we see it, and many customers searching for us will inadvertently find them, thinking we are one in the same company. There is only one "Skip White." We are the original premier eBay seller under this name since approximately 2003. We have no other eBay names, nor are we associated with any other company regardless of the similarity in the name or location. Our official company name is Skip White Performance. Please see the article in the lower part of this ad for a more detailed explanation.

THE BEST FLOWING, BEST QUALITY SBF

ALUMINUM HEADS ON THE MARKET FOR THE MONEY.

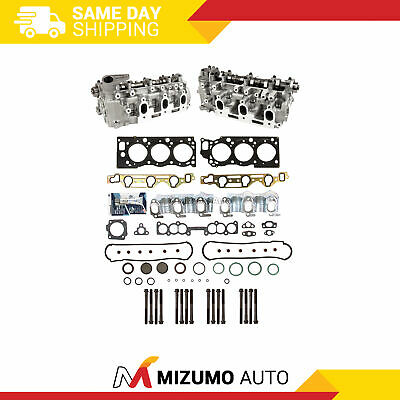

This sale is for one fully assembled set of heads.

The springs in these heads are set up to operate with hydraulic roller cams up to .600 lift. For those running flat tappet cams, see our other listings for these heads with the part number NKB-FORD-272.

The NKB FORD aluminum heads have 62cc combustion chambers with 190cc runners, 2.02/1.60 stainless valves. These heads are not built by Procomp, and have no association with them in any way.

Spark plugs are in standard Ford location.

We certainly know where to draw the line with low end products, and we continue to eliminate parts that we once accepted but that eventually had problems. Sometimes it's not that a particular product has had a problem that leads to its elimination; something better just comes along.

The NKB cylinder heads are that "something better" coming along. Considering the price is only slightly higher than our former line of heads, this has to be the best value in a set of cylinder heads we have ever offered.

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. Details about this alloy are in the lower section of this ad.

A breakdown of the part number.

The NKB stands for "New Kid on the Block"; 190 represents the intake runner size, 274 designates the use of longer valves, and dual springs with a damper setup for hyd. roller cams. You will also see the heads listed with the number 274. The 272 designates the use of standard length valves with single springs with a damper, setup for hyd. flat tappet cams. We also have the valve train setup for solid roller cams, and will have the number 583 rather than 272 or 274. Be absolutely certain of what you need before buying. Feel free to call us if you need assistance deciding what you need for your build.

Below is our flowchart on these heads. All tests were performed on a Superflo 1020 bench by our expert head builder. We stand behind the accuracy. We have noticed many other sellers posting what we consider to be false flow numbers on the heads they are selling. We find this to be nothing short of outright fraud. Of course, flow numbers can vary a few points depending on equipment used and testing methods, but not by 15-25 points. Notice the low lift flow numbers produced by our new heads. That is as important as the upper lift numbers, and it's why these heads produce so much peak power and torque. We are very impressed with the flow numbers of our new heads.

NKB Ford 190cc

Lift

Int.

Exh.

100

65

59

200

113

100

300

164

140

400

214

160

500

245

168

550

254

169

600

259

170

650

261

169

See our other listings for these heads with our Competition Series PBM valves.

Our NKB Ford heads have been designed especially for us. After receiving many recommendations from our engine builders, we came up with the best quality, best flowing heads on the market relative to cost. The only way you're going to get a set of heads that flow as well or better will be to spend at least double the cost or more. These heads are excellent in design and quality. Our choice of hardware and precision assembly also contribute to the performance and reliability of the heads.

ONE YEAR WARRANTY, UNLIMITED MILEAGE.

H

ere is a rundown on the hardware used in these heads and the assembly process.

Comp High Performance Dual Springs, Part Number 987-16

Our Comp springs are 1.43 diameter, with an inner spring and internal damper. Others are using springs that are much smaller in diameter. Smaller diameter springs may be in the correct spring pressure zone, but they usually have a shorter life. Comp springs are made in the USA. All of our engines using the NKB heads use these springs. Spring failures are near non-existent.

Our PBM valves are high temp stainless steel.

PBM/Erson stainless steel race series valves, swirl finished one piece undercut, the same valve we have used for years. Our cost on these valves is nearly double the price of some low cost valves on the market. These are made from high grade non-magnetic stainless. We know for a fact that many head builders use the low cost valves. It is very rare we ever encounter a problem with our valves. We also offer the PBM Competition Series valves in our 66cc heads for the Ford heads.

Below is a copy of one or more of our invoices from Engine Parts Warehouse showing a recent large order for our PBM valves. We have removed the price and our account number for privacy reasons.

This is the best way we can prove to our customers that the valves we use in our cylinder heads are genuine PBM products.

Assembly Procedure

We hone all of the bronze valve guides with a ball berry flex hone to establish not only perfect clearance, but also a semi cross hatch finish for oil retention. We finish off with a natural bristle brush. The heads are then placed in our parts washer and cleaned with high pressure hot water, then pressure dried. Before installing the valves, we apply a heavy coat of engine assembly lube to the valve stems. The coating on the valve stems is essential to protect the bronze guides from gaulding on initial startup.

Our next step is to set the spring pressure to a predetermined pressure using a spring height checking device, most suitable for street rod use. The springs we are using allow for a near perfect seat to nose ratio. Be warned that some sellers of aftermarket heads may not be checking the installed height when assembling the heads, and may not be setting them up to the correct pressures. We have a full scale machine shop with several very knowledgeable engine builders that know and fully understand how to properly assemble a set of heads. Combine the possibility of poor assembly methods with incorrect or low grade hardware, and it is easy to see how failures can result.

We purchase most of our valve train hardware in bulk for our engine program. Below is a copy of one of our invoices from Comp Cams showing several of our rather large purchases of valve train hardware. We have removed the price and our account number for privacy reasons. This is the best way we can prove to our customers that the valve train products we use and sell are genuine Comp Cams products.

IMPORTANT NOTE CONCERNING ROCKER ARM STUDS.

If you have been a regular shopper with us, you will have noticed we do offer some knock-off products that are made off-shore. We do also sell many products made in the USA. We have always been very particular as to the quality and workmanship of such products, while considering the cost. We scrutinize our products very carefully and refuse to sell products that simply don't meet our standards. We have now eliminated another of the low cost knock-off products from our line. The low cost imported rocker arm studs have shown numerous problems unlike those in the past. We have looked at several others on the market, and still find many issues with them that are not acceptable.

Many of the studs had run-out in the shaft of up to an eighth of an inch. This caused major problems with rocker alignment, and depending where the position was when the stud tightened up, would determine the direction of the rocker misalignment. If the warped stud was facing toward or opposite the valve, then the roller tip would would not be centered to the valve tip. This would then create a loss of lift and cause increased wear on the valve tip.

If the warped stud tightened up in a side to side position, then this would allow the rocker tip to be cocked on the valve tip. This would then side load the valve tip with undue pressure, creating a serious wear problem on the side of the valve tip and create excessive wear on the valve guides in the heads. This also side loaded the rocker trunnion and front roller, creating an excessive wear issue in the roller rockers.

We also found a difference in the tread pitch and depth compared to the ARP studs. The rocker studs in an engine are under a tremendous upwards pull and improper thread design may cause the studs to pull out of the head. The ARP studs screw into the heads with a very precise fit and feel.

After thoroughly comparing the ARP studs and several off shore models, I am convinced that we will never offer the off shore studs again, regardless of the price difference. They were never as bad in the past as what we're seeing now. This run-out was most likely caused by improper heat treating methods.

We have rejected many products that are outright junk and would cause serious issues in your engine only to see other sellers offering those same exact products. It's all about learning where to draw the line.

Studs and guide plates are NOT included. Other sellers may include these items but rest assured, they are usually not suitable for these heads. We use nothing but the Dart adjustable guide plates and ARP rocker studs when we build an engine using these heads, as they allow for perfect alignment of your rockers. See our other listings for a full selection of accessories.

See our other listings for valve train related items that you may need for your project.

The part number for the correct studs and our Dart guide plates to be used with these heads is

?

for those running 3/8's size roller rockers, and for those with 7/16's roller rockers the part number is

?

These kits are available in our other listings.

We are glad to offer many great low cost items, as well as the high end products, but will always give careful consideration to quality, functionality, and overall value.

IMPORTANT NOTE, MUST READ!

We have noticed several sellers offering these heads with a one size fits all valve springs for dual use on hydraulic flat tappet and hydraulic roller cams.

We are sure this is not the proper way to setup the heads.

If they have this one size fits all setup somewhere in the middle spring pressure values of what is required for a hyd. flat tappet and a hyd roller cam, then it would be too much for the hydr. flat tappet cam, and create a wear issue. Putting too much pressure on flat tappet cams is a sure way to kill the cam. If these middle of the road springs were used on a hyd. roller cam, then the spring pressure would be too low. Valve float and its damaging effects, along with a loss of performance, are sure to occur.

We use the correct spring for your setup and it is never the same on a hyd. flat tappet as it would be on a hyd. roller cam. As mentioned above, the spring requirements between a roller cam and flat tappet cam are dramatically different. Even the odd ball solid flat tappet cam has its own unique setup depending on the lift. The one size fits all hardware claims also to work on these cams. We know of several sellers offering this insane setup to unsuspecting buyers, and it's not the proper way to set up a set of heads.

We would not even consider using a spring setup like this, and believe me, the simplicity of it is appealing.

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. You may have heard the alloys 355 and 356 being used on many heads. The alloy used on our heads is similar but slightly different. The AC4B alloy is commonly used by automakers in Europe and Japan. Take notice of the Rm value. This value indicates the tensile strength of an alloy. As you can see, it's higher than all the other common alloys in this chart. It's no surprise as to why we have never experienced a failure of any kind with these heads. Zero failures in the casting, zero failures in the seats and guides. We have sold over 5000 pair of these heads over the past four years.

List of Standard Alloy Characteristics

Alloy +B4: H16

AC4B

AC4C

AC4CH

AC4D

AC7A

Mechanical

properties

Rm

(MPa)

345

285

260

320

245

R0.2

(MPa)

250

225

157

240

105

A

(%)

1.6

7.3

16.8

4.1

5.3

Temper

T6

T6

T6

T6

F

Features

High strength, small elongation

Castability: good,

for general purposes

Castability: good

Pressure resistance, corrosion resistance: good

Castability: good

Mechanical properties: good

Castability: good

Pressure resistance: good

Corrosion resistance: excellent,

anode oxidized

Castability:

not good

Examples of

applied parts

Crank cases,

cylinder heads,

and manifolds

Hydraulic parts,

transmission cases,

aircraft parts,

lighting components, etc.

Wheels,

engine parts,

hydraulic parts,

aircraft parts, etc.

Cylinder heads,

crank cases,

fuel pump bodies, etc.

Parts for overhead contact lines,

parts for ships,

business machines,

and lighting components for aircraft

Guide plate recommendation.

Pushrod recommendation

Stud Girdle recommendation.

NKB-190cc RUNNER SIZE 62cc COMBUSTION CHAMBERS FOR FORD ENGINES

Intake Valve Dia:

2.02"

Intake

Port

volume:

190

cc

Intake

Port

Dim:

2.0" x 1.12"

Int

Port

Location:

Stock

Intake Gasket:

Felpro# 1262

Head Gasket: Felpro# 10112

Exh Valve Dia.:

1.600"

Exh

Port

volume:

70cc

Exhaust

Port

Dim:

Exh

Port

Location:

Stock location & bolt pattern

Exhaust Gasket:

Depends on what type exhaust you're using. Best to try and match up the gasket to your header or manifold

Flow, Intake:

See chart above.

Flow, Exhaust:

See chart above.

Head Bolts:

ARP 154-3601

Rocker Studs: ARP 100-7101 (for 7/16" Rocker Arms)

Manifold:

Most any. Our line of intakes fit very well on the NKB heads.

Milling:

Min. Down to 58.5cc or 64.5 = .060"

See info in this listing for details on this.

Pistons:

Most

aftermarket pistons.

Push Rod length:

Push rod Guide Plate:

Comp Cams 4835-8 (for 5/16" Diameter Pushrods)

Retainers/Locks:

Chromoly Steel Retainers, with

10

°

Comp brand machined locks are used on all of our heads.

Spark Plug:

Autolite #3923 14mm x 3/4" reach

Spring Pockets:

1.550" OD

(.030" deeper max)

Springs:

Comp

1.43 large size outer diameter with internal damper.

Valve Length:

5.015" (+.200") for hydraulic roller cams.

Valve Stem Dia:

.3415"

-

11/32"

Valve Train:

STD

SBF

3/8" or 7/16" stud mount

Valve Guides:

1/2" OD

Int = Mag-bronze

Exh = Phos-bronze (.002" press)

Valve Guide length:

1.950"

Valve Guide clearance:

.0014" - .002"

(with our .3415 dia. valve stem)

Valve Guide Spacing:

1.890"

moved .030" from stock

Valve Seats:

Hardened Ductile Iron,

.006" press

Valve Seat dim.

Standard

Valve Seat angles:

Int = 32

°

- 45

°

- 60

°

- 70

°

Exh = 37

°

- 45

°

- radius

Stud Girdle:

Torque:

Head Bolts = 65 ft/lb

Rocker Studs = 55 ft/lb

Manifold = 30 ft/lb

Block Use:

Any

SBF

Iron or Aluminum

Weight:

59-61

lbs fully assembled pair.

A final note...Skip White Performance...About Us

I'm sure many of you have noticed there are 2 high performance engine builders in Kingsport, TN with similar names, leading to a great amount of confusion.

We are Skip White Performance, NOT White Performance and Machine.

Due to the name similarity, many customers looking for us online inadvertently find them, thinking we are the same company. Definitely not...there is no connection between the two companies. We don't have a problem with free enterprise (competition). However, when the competition builds their foundation on such things as a name similarity and their supposedly long history of being in business, then we think it's about time we set the record straight.

We have owned White Performance since 2003, with the exception of the machine shop, which was owned by Fred White at the time. He continued to operate the machine shop and build engines for us while we continued selling online under the eBay user ID of skipwhite and the eBay store name of whiteperformance1.

Due to their limited production capability and many disagreements about the engine and head building process as well as workmanship, we opted to open a full scale machine shop of our own a few years later. Fred White began competing against us even though our contract had a non-compete clause in it.

As our business grew, we opened a second, much larger warehouse and machine shop around 2011, located on Brookside Ln. in Kingsport TN. By putting heart and soul in this company, we have become the number one street rod engine builder in the nation.

Fred sold his shop to an investor in 2016 and the new owners continue to reap the benefits from this confusion between the two shops. This investor lacked any knowledge of this industry. They continue to use the White Performance & Machine name. Contrary to what is posted on their website, Fred White is no longer associated with the company in any way. Their main spiel in advertising is, "In business since 1979," when in fact, we purchased the White Performance company in 2003, with the exception of the machine shop.

All in all, we have been in this business going on 17+ years. Skip White's passion has been owning and building street rods for 47 years on a personal level. The knowledge he has gained over time has allowed him to venture into this business and succeed to a very high level.

The great pretenders continue capitalizing on our success due to the name similarity, but have been degrading our reputation. We have been getting calls nearly on a daily basis from people that now realize there are two shops in this town with very similar names. Customers complain of serious problems in getting their orders in a timely manner from them. They think they purchased their cylinder heads from us. Due to the confusion, there is an increasing amount of negative feedback that is affecting our name within the street rod community, when in fact we have a near perfect reputation in this industry. We have an "A+" rating with the Better Business Bureau and we have maintained the A+ rating for many years.

FAST FORWARD TO PRESENT DAY...We have become the largest street rod engine builder in the nation. Our engines, rotating assemblies, and cylinder heads are built to very high standards and shipped to our customers in a timely manner. We are a premier seller on eBay with a positive feedback score of well over 206,000 and growing, as compared to our competitor’s score of approximately 24,000.

Our engines are custom-built to our customers' specifications and are shipped in approx. 2-5 weeks, perhaps sooner, depending on the season. Our rotating assemblies usually ship out in about one week or less, and our heads ship in about a week or less.

We are not responsible for collateral damage caused by the use of this product.

RETURN POLICY

Should a problem occur, please contact us. If a return is necessary, please contact us for an RGA number and return authorization. The RGA number must be included on the return label. If an item is returned without an RGA number, it will not be processed. A full description of what the problem is needs to be included with any returned product with your contact info, and proof of purchase. Even though you may have explained the problem to us, and been granted permission to return the product, we must have a written explanation and a contact number included with the product. It is also recommended that you include the name of the person from our company that you have been in contact with. You must send the item back to us in a trackable manner (USPS Priority Mail, FedEx, etc.) and keep the tracking info of the returned product. Please give ample time for returns to be processed. Following these guidelines will make the return process work as it should.

PAYMENT AND SHIPPING DETAILS.

We offer great discounts on shipping. You only pay

the full shipping fee on the highest shipping cost of your items, and

HALF PRICE

shipping on all additional items. Few offer discounts on shipping such as this. Our checkout system will automatically calculate your shipping discount at the time of final payment, providing you consolidate your payment.

You may receive a verification and tracking number shortly after purchase, but this does not necessarily mean that your product has shipped. It would be fair to say that 98% of products will be going out the day the shipping label is issued. On occasion, the product may not ship out until the next day after the label has been issued. Most products purchased late in the day will not be shipped until the next day.

If you checkout and start over, the auto calculator will not recognize the multiple purchases, and there will be no shipping discount.

FedEx is our primary shipper. We are unable to ship to APO/FPO addresses. Help us ship your order promptly by including your physical address at checkout. If your order MUST be shipped to a

PO

BOX, please contact us. Additional charges may apply. Below is a map representing the estimated delivery time to get to you from our location.

Delivery times may vary, especially during peak periods.

FedEx Home Delivery delivers Tuesday - Saturday. If a package leaves here on a Thursday, and you are in a 2 day delivery zone, your package may deliver to you on Saturday. If you are in a 3 day zone, and your package leaves on a Thursday, you should receive it on the following Tuesday. Expedited shipping is available upon request for an additional fee. Please contact us for rates. The estimated shipping time is usually as the map shows, but many factors can delay this.

Hawaii

and

Alaska

have a 6+ day estimated delivery time.

The shipping quoted in this ad is only for the

48 continental

United States

. If shipping to anywhere else, please contact us. The half price shipping on all additional items also only applies to items that are being shipped in the 48 continental

United States

.